Share this post

Beer bottle sizes and their surprising history

Do you know your Growler from your Howler, and your British from your Ballena? If these words are gibberish to you, let us introduce you to the fascinating world of beer bottles!

There’s a whole range of bottle shapes and sizes out there that house the world's most famous alcoholic beverage, and they have interesting names too. If you’re a zythophile (that’s the posh name for ‘beer lover’), here’s a brief overview of the modern day beer bottle sizes and shapes.

Beer bottle sizes: a brief history of the humble beer bottle

Where, when and how beer originated is hotly contested by historians. What we can all agree on is that the earliest recorded description of beer brewing and bottles that we have to date is on an ancient clay tablet from 1800 B.C Sumer, historically the area between the Tigris and Euphrates rivers. From that ancient record, it appears that beer was sipped through straws from Sumerian jars.

The evolution of beer bottle sizes in the early 1700s

Jump forward a few thousand years, and we get to the emergence of the first glass beer bottles. These were invented in the early 1700s, and early beer bottles were sealed (‘stoppered’) by corks, much like traditional wine closures. Early beer bottles were blown from thick, dark glass, and had long necks like wine bottles.

As brewing techniques progressed, so did beer bottle sizes and shapes. By the end of the 18th century, beer bottles were starting to take on the typical short-neck and low-shouldered form we see a lot of today. The ‘porter’ was born.

Beer bottle modifications in the mid 1800s

In the mid 1800s, the invention of lager spurred a further modification of bottle shape. Early lager bottles had longer necks and steeply sloped shoulders. Then, shortly after, ale and lager bottles devolved in a way that made them look much like late 1700s beer bottles.

Design innovations in the 19th century and beyond

In the latter half of the 19th century, several distinct bottle sizes and shapes started popping up.

These bottles included:

- Weiss (German wheat)

- Squat porter

- Long-necked export

Let’s not forget that as well as glass, stoneware bottles were still popular at this time. However, their heavy weight and closure limitations would lead to them being phased out at the turn of the century.

Most of today’s traditional beer bottle shapes arose throughout the 20th century. In America, short necked-and-bodied ‘stubbies’ and ‘steinies’ emerged directly thanks to the glass industry’s retaliation against rising beercan popularity in the 1930s. In the latter part of the century, most British brewers chose to bottle in the ‘London Brewers’ Standard’ - a brown glass bottle that came in pint, half-pint, and nip sizes. Glass ‘growlers’ were invented late, in 1989, by an American microbrewer. These hefty glass beer jugs allowed draft beer to be taken home, which was historically done in buckets and tin pails.

Those ‘shoulders’ we keep mentioning remain in modern beer bottle design mainly for aesthetic reasons. Their original function was to provide a handy place for the yeast residue and dregs to collect, so that these didn’t pour out into the glass with the beer. Nowadays, most beer is filtered, so this design feature is no longer needed. Unless you’re bottling a yeast beer like a Belgian beer, of course.

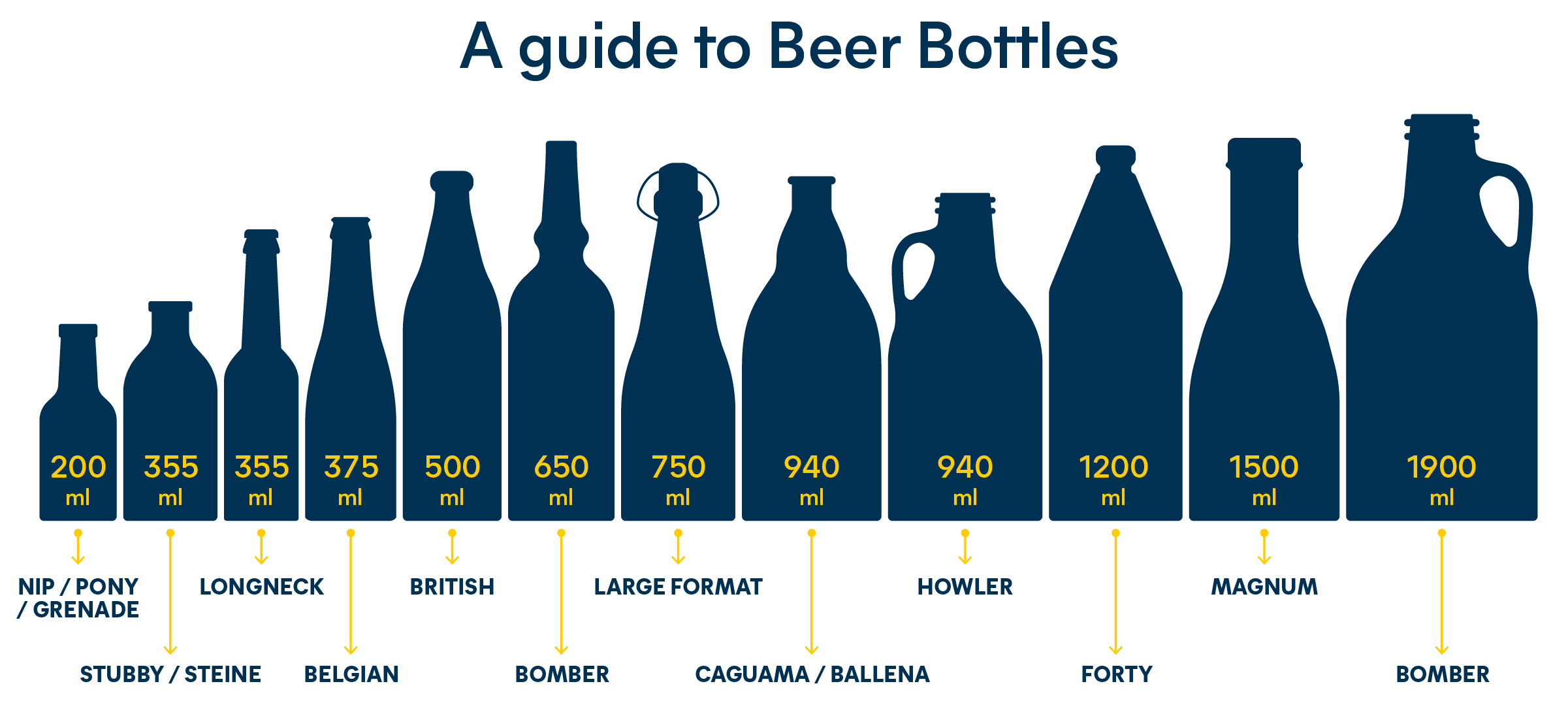

What sizes are beer bottles?

Now that you know a bit of beer bottle history, let’s consider today’s most popular beer bottle sizes.

In the United States, bottles are typically 355 milliliters. Besides the standard-sized beer bottles, there is also a "split" bottle that holds 177 milliliters. These bottles are for more potent brews.

Larger bottles hold 650 millilters. The classic Champagne-style 750-milliliter bottle with a cork and wire cage is also popular.

The standard size for a bottle in the United Kingdom is 500 milliters. Smaller bottles usually come in two sizes — 275 or 330 milliliters.

In Europe, 330 milliliters is standard.

Hillebrand Gori: your go-to partner in beer shipping

Hillebrand Gori has worked side by side with beer brewers for decades. We’ve mastered the unique ins and outs of beer transportation to help you with any aspect of moving beer. Hillebrand Gori also offers several cutting-edge keg management services.

Our keg services include reusable keg logistics with Kegspediter, keg leasing with kegFleet, and keg tracking with the KegID app.

We can also help plan the transport of your malt, hops, bottles, and any other packaging or point of sales materials. Transporting beer from brewery to bar has never been easier!

Get in touch and discover how we can help you with your beer products.

Published 27th February 2023, updated 11th March 2024

Beer bottles are pressure-sensitive and need to be handled with care. The size and shape influence how they’re packaged and shipped in containers, which affects costs. Larger or irregularly shaped bottles may take up more space and require more care to prevent breakage during transport.

The amount of raw material used and the production method can have an impact on the sustainability of a beer bottle. Some breweries use lighter bottles (under 220 grams) or cans, which can have a lower environmental than standard glass.

Work with an experienced logistics provider like Hillebrand Gori, that specializes in beer shipping and has developed efficient, sustainable methods. These include optimizing transport routes, considering alternative modes of transport, and using sustainable packaging options like reusable kegs.

Specific regulations depend on the country of import and export. For example, the Alcohol and Tobacco Tax and Trade Bureau in the US, regulates the shipment of alcoholic beverages and only allows the transport of beer from the brewery for consumption or sale in barrels, bottles, kegs or similar containers.

How can we help your business grow?

.png?sfvrsn=312da2e2_1)